The Generation Global team was thrilled to work with a Bo 105 helicopter for this project, which involved a complete interior refresh. Working in both the cabin and the rear cargo hold, we replaced seating, flooring, the cargo ceiling, the cabin rear bulkhead, and the control boots. The end product was a truly transformed interior, and we’re proud to share it with you. Almost every part used for this project can be found at Generation Global’s online shop.

GALLERY

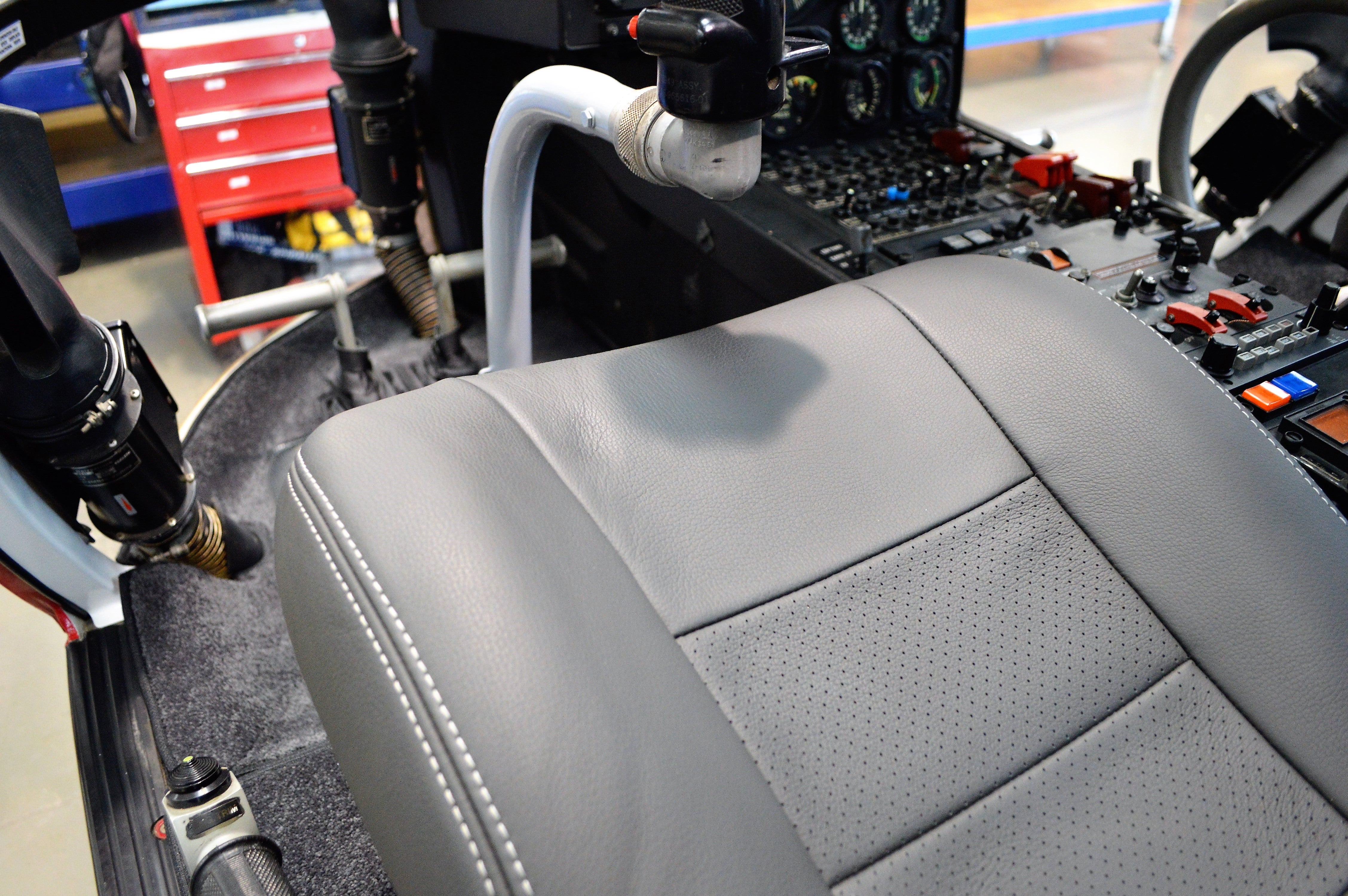

The seat upholstery we used was manufactured with a subdued, Lead Grey (ADI-1111) aviation leather. Their design featured perforated (SP1) leather on the inserts and decorative Titanium double stitching on all exposed seams. Sporting a Gen I design complete with new foam cushions and leather dress covers, these seats combine functionality with looks and comfort.

Crew seats also featured shell covers that provide protection from scratches, dirt, and dust, helping seats stay looking newer for longer. The shell covers were made from the same leather as the seats and have handy document pouches – mesh pockets with elastic closures - on their backs. To complement the seating design, we wrapped the rear bulkhead panel with the same lead grey (ADI-1111) leather. The panel itself had a firm, durable foam at its core, and was carefully glued into place on the rear bulkhead.

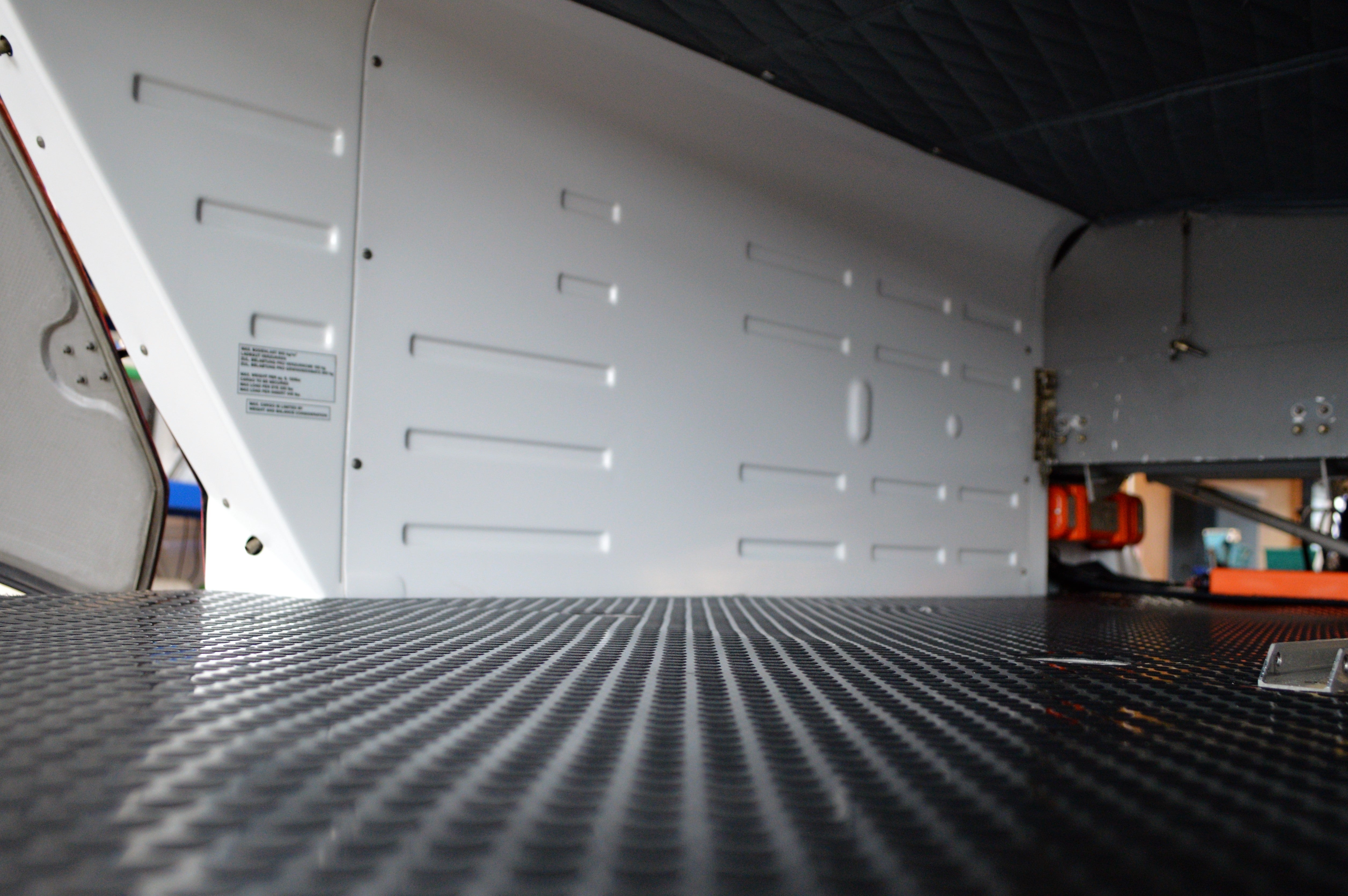

For the floorcoverings of this helicopter’s cabin, we used Zimmer (WN-120) carpet. Both carpet or penny mat (MW-200) flooring can be used on the Bo 105, but we thought the Zimmer carpet was a better fit for this project. The carpet comes as a three-piece set - each of the two crew seats has its own piece, which sits in front of the seat, while the final piece sits between the crew seats and the rear seats. The flooring for the rear cargo bay is MW-200 vinyl and comes in two colour styles: black or graphite. We also fitted out the rear cargo bay with ceiling blankets. Made from absorbent padded material, these specialized pieces help muffle sound. While not available on our website, we can often supply pieces like these on request.

To finish out the interior, we fitted some of the Bo 105’s exposed parts with sleeves made from soft, malleable pieces of black (ADI-1091) leather. Fittings we applied – all of which were custom-sewn to adhere perfectly to the shape of the Bo 105’s controls – included cyclic and collective boots. Sleeves were attached under the carpet, for a clean, seamless look. In addition to the boots, we also placed a gust lock cover with a transparent sleeve for its dome close.

THE CLIENT

Our client for this project was a New Zealand-based maintenance organisation that is expanding into the aircraft parts market. The company has operations in both the United States and New Zealand, having acquired a variety of aviation companies over the years to widen its scope. The helicopter that we worked on had been imported from Japan, having been used by a news company. Now looking as good as ever, we’re excited to see where it heads off to next!