DYNAMIC SEATS

Generation Global has significant experience and expertise in the development and certification of seat covers and cushions in compliance with the 2X.562 dynamic seat requirements. The key change for aircraft interior manufacturers is that dynamic seats are tested and pass as a system including the structure, seat track fittings, energy absorbers, stroking mechanisms, restraints & anchors, and cushions & upholstery.

TESTING

In the 1990s the FAA introduced amendments to FAR rule part 2X.562 which included the addition of dynamic seat testing to seats. Previous amendments had only included static testing requirements and this change brought about the requirement for seat manufacturers to develop what they call ‘energy-absorbing seats’. The purpose of energy-absorbing seats was to increase occupant survival of accidents. The previous TSO for seats meeting the static requirements was TSO C39. The FAR 2X.562 dynamic requirements were then reflected in what we know as TSO C127. A TSO sets out a defined Minimum Performance Standard (MPS) for the manufacture of seats. All aircraft designs type certified after the amendment now must include seats that meet the 2X.562 requirements.

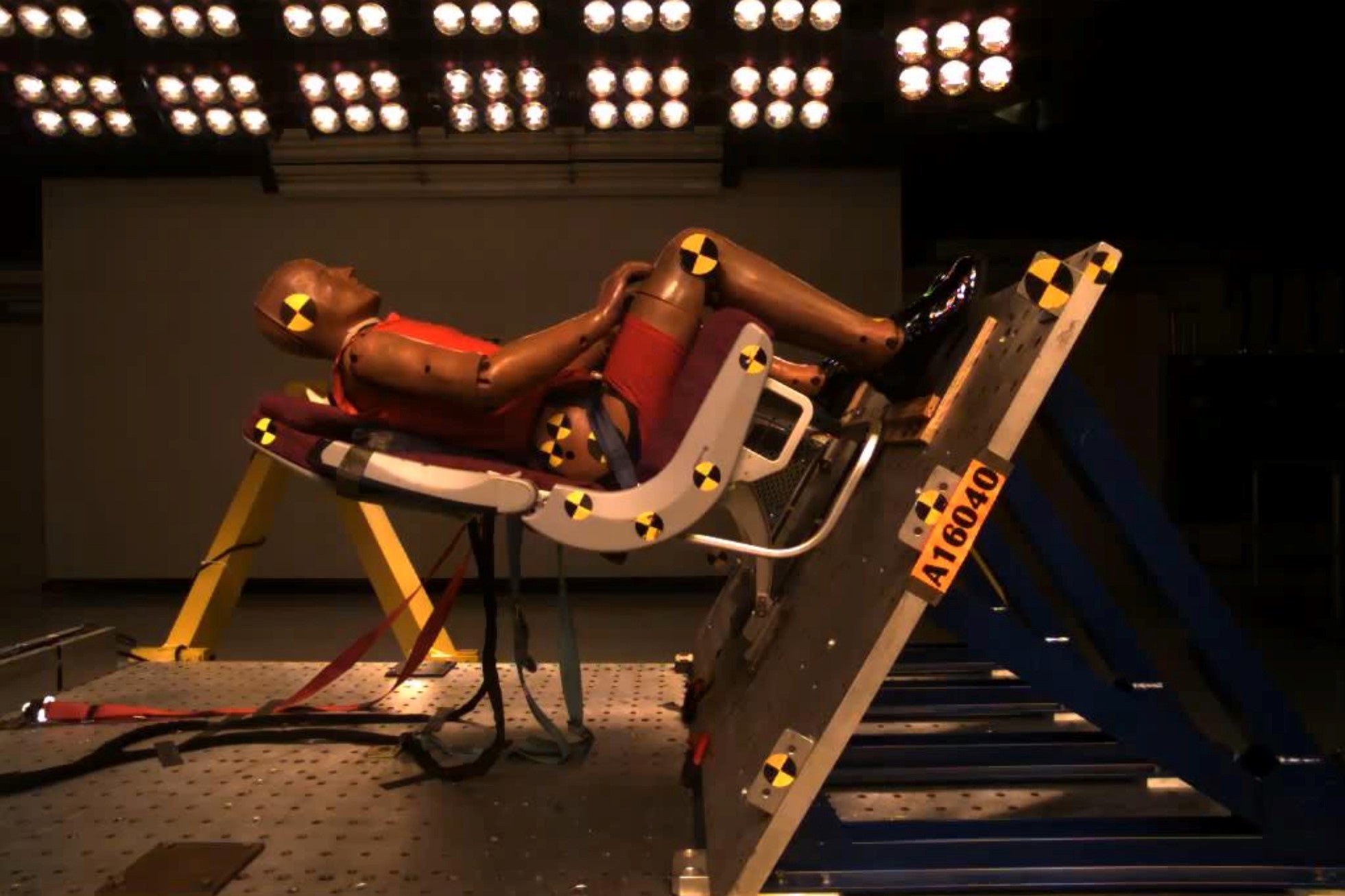

14G DOWNWARD TEST

The Dynamic 14g downward test is primarily used to measure the lumber load that the occupant experiences. The 2X.562 requirement is that the lumber load should not exceed 1500lbs. Watch this video to see Generation Global conducting a 14g downward test and the effect on the occupant's spine.